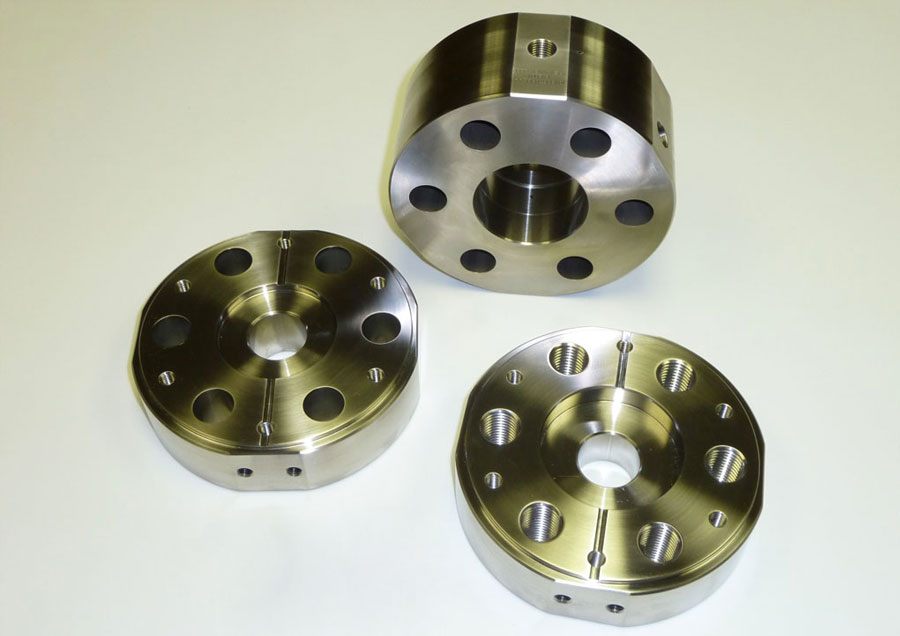

Meeting customer requirements for high-precision machining

To meet our constantly demanding customer base, the Apex team pushes the envelope on ever increasing machining challenges. The latest month saw a group of Inconel 718 components destined for the resources sector. These component s will be used for instrumentation purposes in oilfield deep hole drilling. There is good demand in the oil patch for high precision machining services such as those Apex offers. With overnight shipping distance is not an issue. Our customer approached us with many opportunities to manufacture complex machined components in rare, exotic materials.

Meeting the challenges of high-precision machining

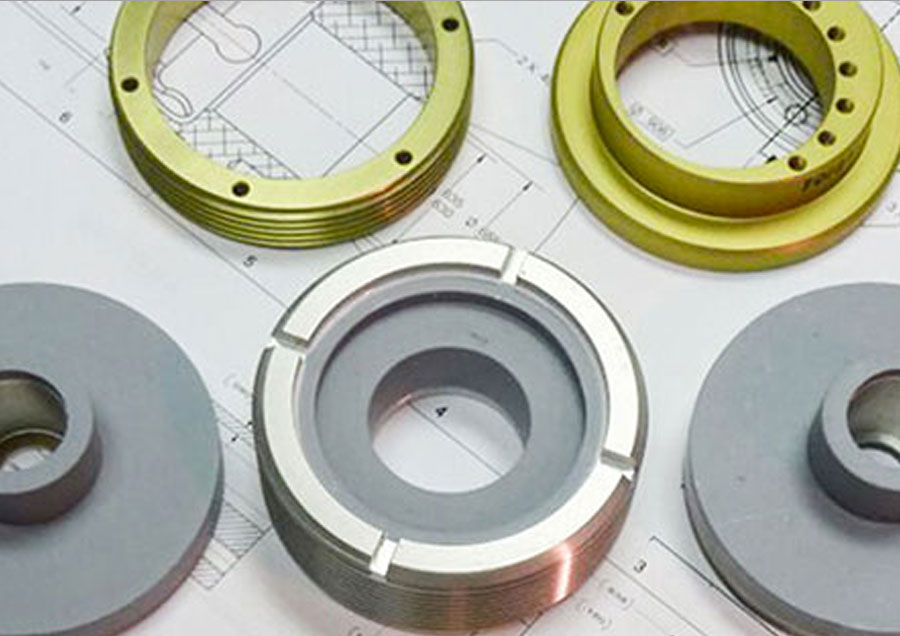

At first glance these parts look relatively straight forward. This may be to the untrained eye but numerous features pushed some manufacturing limits. To assist us with this challenge we called in many of our known tooling suppliers from the aerospace sector. High diameter to depth ratio drilling and tapping were the main concerns at the onset of the job. There were also saw-cutting issues. $70 blades were only able to cut 3-4 blanks. Carbide saw blades may be a better choice but are not always the best solution in jobshop world.

Acquiring special tooling and materials

As with most jobshops the special tooling and material required, takes almost as long to acquire as it takes to do the job. Getting close to Christmas was not making it easier. Regardless, we started the job with most tooling on hand. Expect 5-10% tooling cost for jobs of this nature. Tools wear very quickly in high nickel chrome materials so make sure you have extras. The due date was just before Christmas and we were at the final stages. Misfortune occurred when some high performance tools failed to achieve their advertised expectations.

Working to thight deadlines

Scrambling to meet delivery all 3 shifts at Apex attempted to get these parts out with underperforming tools. This time our on-time delivery performance suffered but fortunately the client allowed us to push the date. Lesser performance tools were acquired but with the extreme machining skills at Apex we were able to complete the job with dignity and a reasonable margin …first time round. Congratulations to the Apex team and an understanding customer.