Invar is an austenitic iron-nickel alloy with low thermal expansion, known for its exceptional dimensional stability. It is strong, tough, and ductile, with a useful degree of corrosion resistance.

This alloy remains magnetic in the temperature range where it exhibits low expansion characteristics. It is the standard alloy for low expansion up to 204 oC.

For higher-temperature applications, alloys with a higher nickel content are recommended.

Applications

It is used where high dimensional stability is required, such as in precision instruments, clocks, seismic creep gauges, engine valves, and antimagnetic watches.

In surveying, when first-order (high-precision) levelling is required, the levelling rods used are made of Invar, rather than wood, fiberglass or other metals. Spacers of this alloy have been used in some pistons to limit their thermal expansion inside their cylinders.

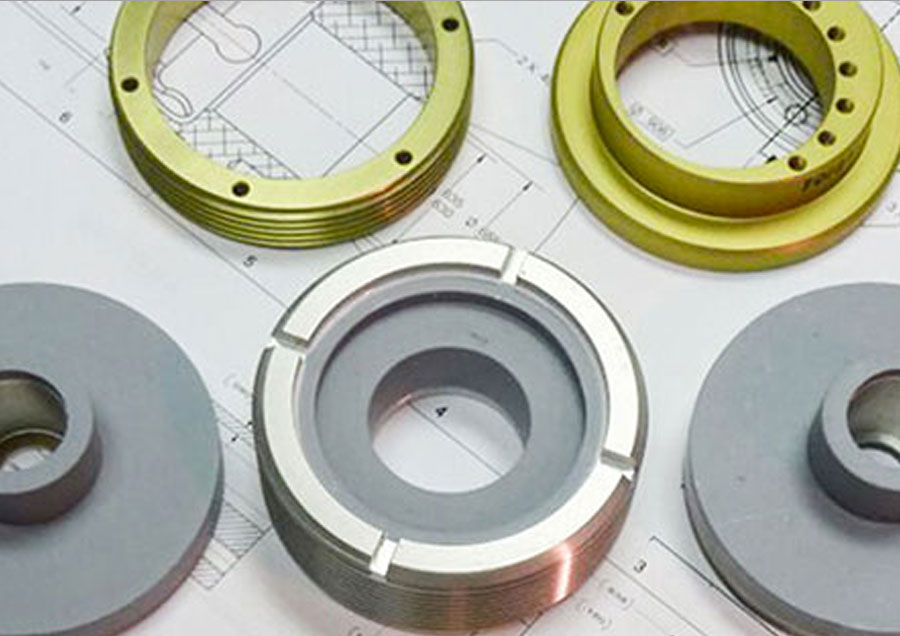

Apex expertise in Invar machining

Apex has a long history of working with Invar. Parts produced with Invar are generally used for precision instrumentation. Parts are generally small, as the price of Invar can vary between $20 and $30 per pound.

Machining of Invar is reasonable with the use of carbide tooling. When machined with carbon, it can be machined at about half the speed of steel. The main challenge in machining iron-nickel alloys lies in eliminating the burrs generated by the cutting process.

Each machined part requires its own deburring method. Deburring is often carried out under magnification, due to the small size of parts.

Precise tolerances and measurements

Because of their small size, parts tend to have much tighter tolerance callouts. The tightest tolerance achieved at Apex was .002mm (.00008”) in a small hole, using Wire EDM and measuring with an OPG Vision System.

Choosing the right tolerance on a part is crucial. One decimal place can change the process and price dramatically. The parts also need to be checked with the proper measurement technology.

Invar information requests

Please feel free to email Apex with any queries you may have about your Invar manufacturing requirements.

We specialize in the production of Invar parts and ensure that each part meets the most stringent tolerance and quality requirements.