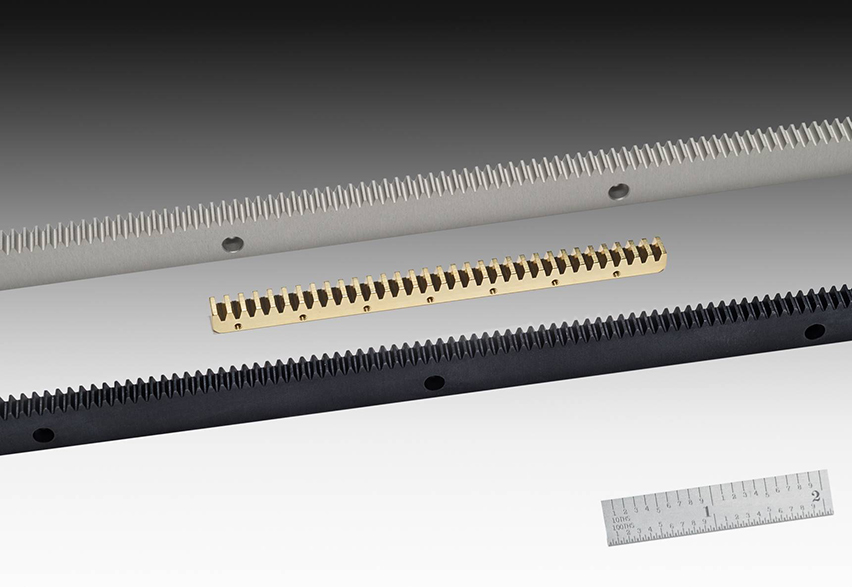

Custom Gear Racks

Various OEM’s

As a leading manufacturer and supplier of mechanical parts, Apex Precision Inc. features a broad selection of precision gear racks. We specialize in manufacturing custom gear rack designs, and will gladly modify and add features to our standard parts. We’re committed to ensuring your projects are done accurately, efficiently, and on budget.

For compatibility with different materials and applications, Apex Precision Inc. offers several material options for gear racks including:

- Stainless Steel 300 and 400 series

- Aluminum 2024, 6061 and 7075

- Steel

- Brass

- Titanium

Pitch Range: 24 to 120 – 20in in length

What are typical gear rack applications?

Serving industries as diverse as medical, research, manufacturing, cinema graphics, electronic devices, photocopier/printer, and furniture building. The common thread that joins our gear rack and pinion offerings is our commitment to quality, precision, and selection. The list of industries and applications below showcases the range of our expertise and our capacity to produce high-quality parts. Industries, functions, and products include:

- Research/Quality – Level/Depth Gauges, Dials

- Quality/Inspection (Optics Adjustment, Part position) – Microscopes, Comparators

- Medical (Linear Adjustment/Holding) – Retractors, spreaders

- Control Systems – Linear Position, Actuators

- Manufacturing – Rapid Adjustment, Height Adjustment

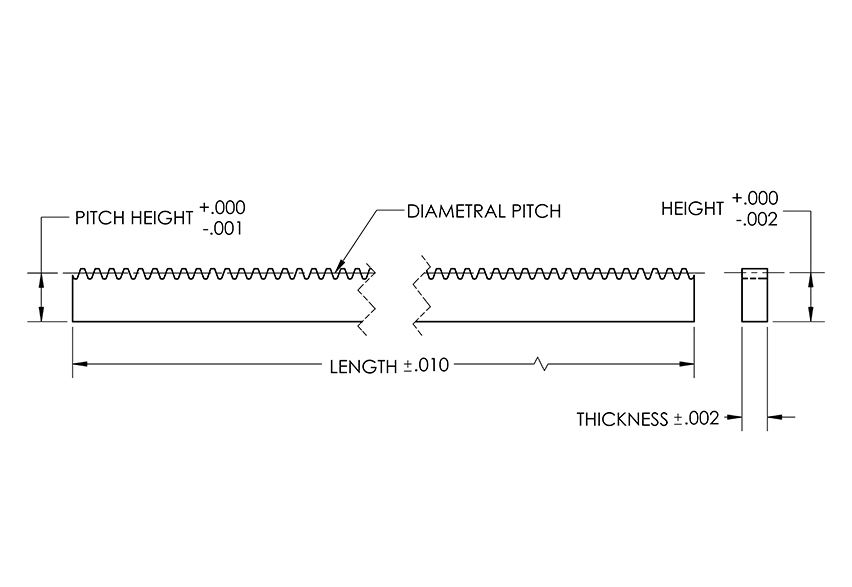

Tooth accuracy quality:

Tooth profile and lead deviations to grade A10 per AGMA 2015-1-A01, Pitch deviations to grade A7 per AGMA 2015-1-A01. Same starting point of tooth geometry at both ends of gear rack can be maintained accurately from parts to parts for special application of installation.

Matching spur gear available.

Standard delivery 4 weeks.

Contact Apex for pricing.

Testimonials

-

"We have used the services of Apex Precision successfully on several occasions. The fabricated parts in question are complex machined components requiring a high degree of accuracy"

Mark Pankhurst

Purchasing Manager at Sander Geophysics Ltd.

-

“ . . . Apex has always been one of our top suppliers. Since the inception of Intelligent Hospital Systems, Apex has been beside us step by step creating the perfect machined parts for our medical device, RIVA. Employees of Apex always treat their Customers with the utmost professionalism. . . ”

Sandy Garden

Buyer / Planner

-

I have been working with the APEX Team for over 12 years on a multitude of different projects, from simple to extremely complex. I have had nothing but great experiences with them. They are not simply a high precision machine shop - they thrive at providing support during the conception phase. They have provided CAD and design support and have always delivered projects on-time and within budget. I cannot do other than highly recommend them to anyone I speak to. Thank you APEX!

Michael J Froncioni, BEng., BSc.

Senior Manager, Supplier Quality Engineering