Medical Device Services

Apex Precision has been working hand in hand with medical device companies to help with the design and manufacturing of complex tooling, jigs, fixtures and components for over 15 years.

Our on-site Medical Device Engineers have over 15 years’ experience in process tooling, process development in all areas of catheter manufacturing and assembly. The following are just a few areas that are at the core of our expertise in Medical Device:

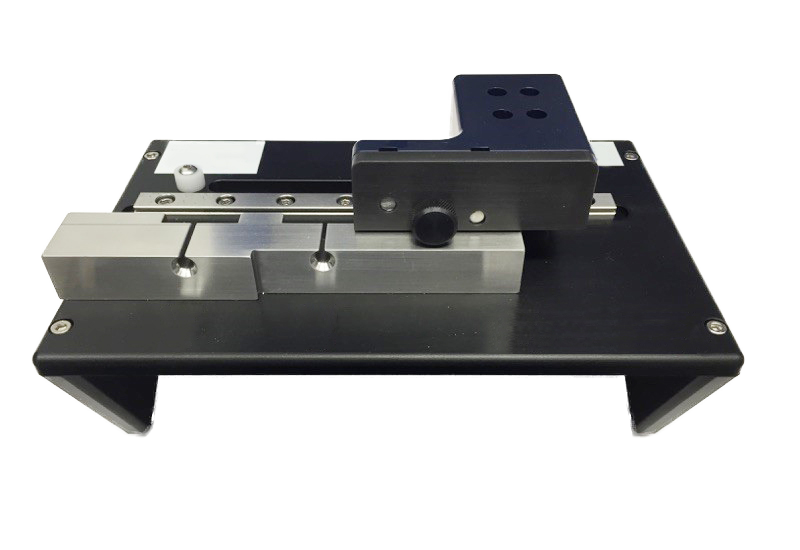

- Balloon Catheter trimming fixtures capable of trimming balloon necks with absolute flush cuts and to precise lengths. Can be used to cut urethane and PET balloons.

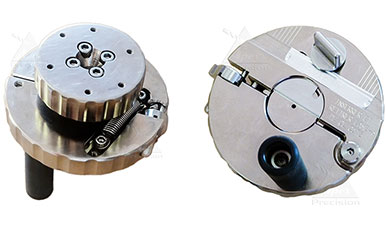

- Rotary cutters for trimming braided shafts to length with flush cuts and no protruding braid ends.

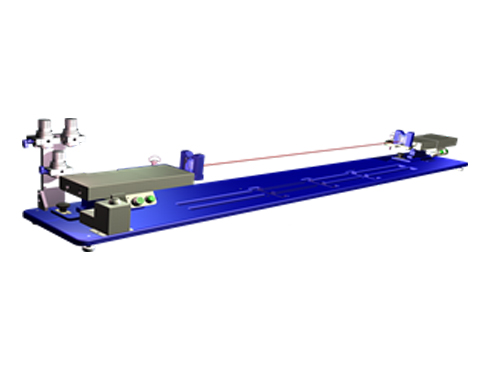

- Catheter reflow mandrels from very complex multi lumen, to single and double lumen as well as stepped mandrels, ranging from 3 to 20 French in size (1mm – 6.7mm in diameter) and up to 48 inches in length.

With our vast experience in Medical Device Manufacturing, we also offer consulting services for any process development and for any process issues you may be experiencing. Our engineers are experts at resolving process issues using Lean Manufacturing methods, mainly the DMAIC method – a systematic approach to root cause analysis.

Testimonials

-

"We have used the services of Apex Precision successfully on several occasions. The fabricated parts in question are complex machined components requiring a high degree of accuracy"

Mark Pankhurst

Purchasing Manager at Sander Geophysics Ltd.

-

“ . . . Apex has always been one of our top suppliers. Since the inception of Intelligent Hospital Systems, Apex has been beside us step by step creating the perfect machined parts for our medical device, RIVA. Employees of Apex always treat their Customers with the utmost professionalism. . . ”

Sandy Garden

Buyer / Planner

-

I have been working with the APEX Team for over 12 years on a multitude of different projects, from simple to extremely complex. I have had nothing but great experiences with them. They are not simply a high precision machine shop - they thrive at providing support during the conception phase. They have provided CAD and design support and have always delivered projects on-time and within budget. I cannot do other than highly recommend them to anyone I speak to. Thank you APEX!

Michael J Froncioni, BEng., BSc.

Senior Manager, Supplier Quality Engineering