Aeronautical equipment manufacturing

Aeronautical equipment manufacturing has never been more challenging. Apex works with aircraft customizers mostly for Bombardier Global and RJ aircraft. Construction deadlines are strict, from the moment the hulls enters the hanger to delivery of the aircraft to the customer. Accordingly, Apex production is geared to producing the required material as quickly as possible, while maintaining optimum quality.

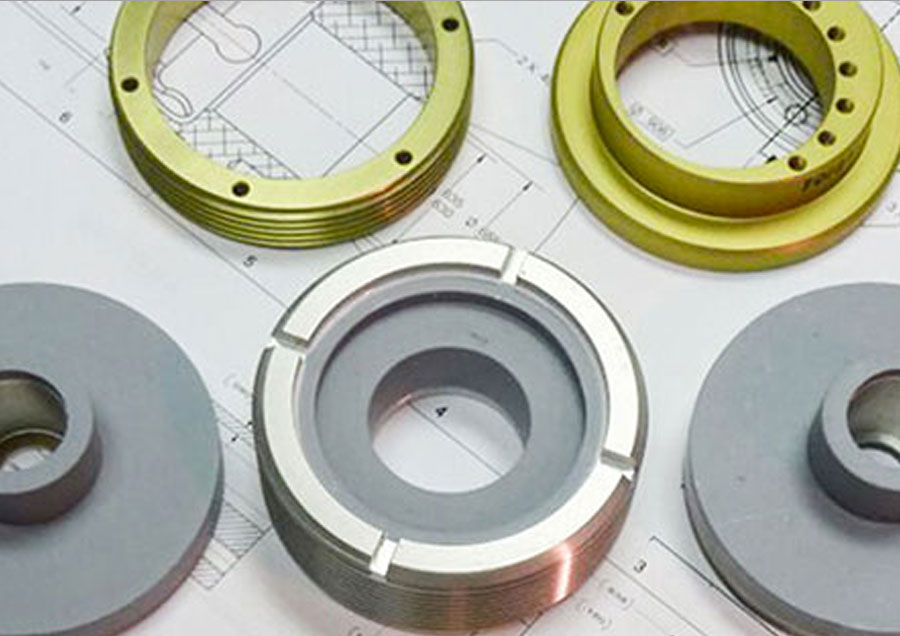

Casting and machining complexity in aeronautical equipment

The image shown below a typical requirement. At first glance, it appears to be a simple molding, but in reality, it is actually very complex, requiring 3 machining disciplines to complete. Curved top section requires 3d , C.N.C. milling. Furthermore, the inside intersection with barely no radius, requires wire EDM, while the 2 pockets require plunge EDM, or EDM sinking as we call it. The reason for the plunge EDM is due to the internal square corners. Therefore, we encourage engineers to use plunge EDM sparingly as it can get quite expensive. Fortunately, in this case, this was a simple burn.

Team and production times

A team of 8 skilled technicians were pulled together to produce these components over a 5 week time frame. More often than not, the delivery date dictates the machining process to be chosen or the recipe to build these components. Keep in mind this is a new component for Apex, and there is no recipe. Consequently, everything Apex builds or designs requires is own production process.

Apex production capacity

On average, Apex fills 1500 orders per year ranging from prototypes which are usually low quantity to production runs of 1K -10K. Apex runs 3 shifts so prototypes get planned out and built on the day shift while the production is done on second and third shifts. Component planning, creation and development are a big part of our day and Apex has “what it takes” to get the job done.

Don’t hesitate to contact us, we’ll be happy to answer any questions you may have.