Medical Equipment

Various OEM’s

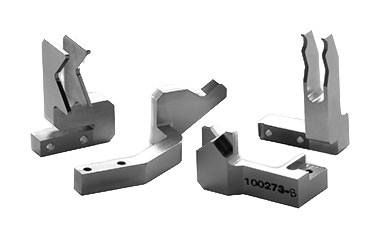

Apex has a long history of assisting Medical Original Equipment Manufacturers (OEMs). One part of our relationship is producing various components for their products. Medical components require exact precision with an extreme level of cleanliness. Most of these components require optical inspection to ensure no evidence of foreign debris nor raised edges (burrs).

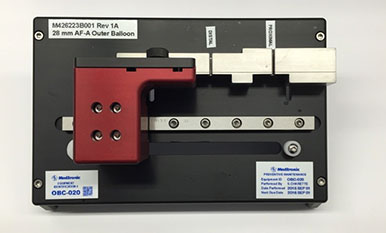

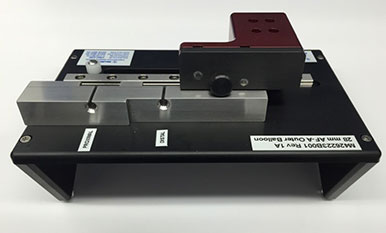

Apex also assists Medical OEMs in the fabrication of precise tooling assemblies which are used for production of components. We help with all stages, including design, testing and creation of the required hardware. Customers are welcome to access our many years of experience.

Testimonials

-

"We have used the services of Apex Precision successfully on several occasions. The fabricated parts in question are complex machined components requiring a high degree of accuracy"

Mark Pankhurst

Purchasing Manager at Sander Geophysics Ltd.

-

“ . . . Apex has always been one of our top suppliers. Since the inception of Intelligent Hospital Systems, Apex has been beside us step by step creating the perfect machined parts for our medical device, RIVA. Employees of Apex always treat their Customers with the utmost professionalism. . . ”

Sandy Garden

Buyer / Planner

-

I have been working with the APEX Team for over 12 years on a multitude of different projects, from simple to extremely complex. I have had nothing but great experiences with them. They are not simply a high precision machine shop - they thrive at providing support during the conception phase. They have provided CAD and design support and have always delivered projects on-time and within budget. I cannot do other than highly recommend them to anyone I speak to. Thank you APEX!

Michael J Froncioni, BEng., BSc.

Senior Manager, Supplier Quality Engineering