High Precision CNC Milling

Various OEM’s

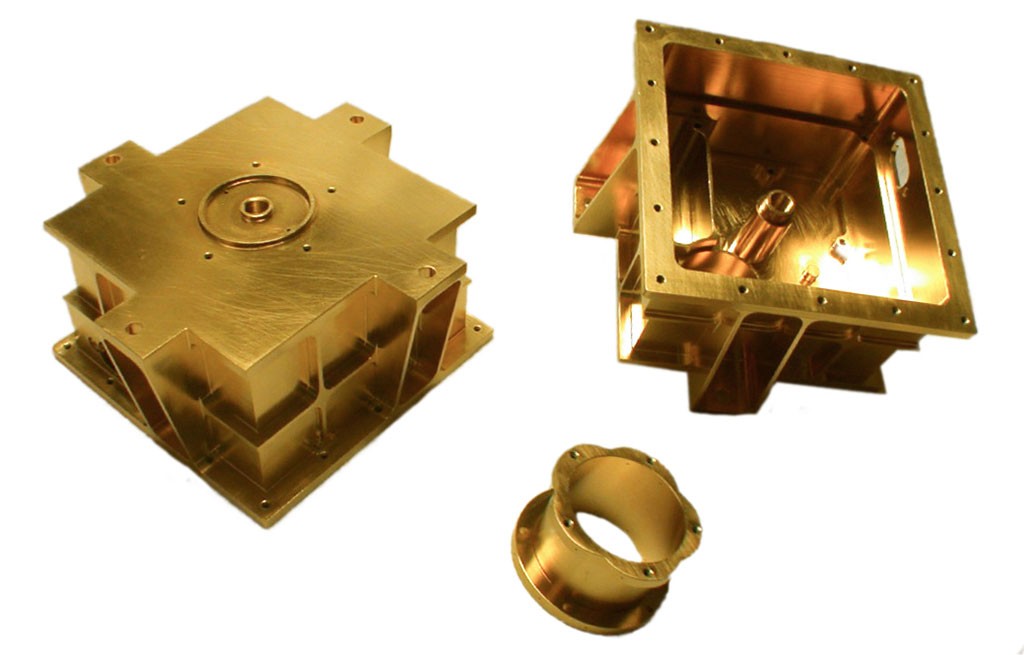

Apex originally started as a turning/milling shop back in the early-90’s. At that time, Apex mostly worked on space-craft hardware in materials ranging from super invar to Vespel. The experiences gained over those years have led us to do work for many other industries with similarly challenging applications.

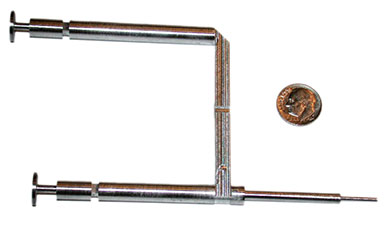

High precision milling services remains a core competency of Apex today. We are doing much the same work today but within a CNC milling environment. We work to any precision with quantities from single units to many thousands.

Apex maximum milling capacity is X-60”, Y-27” and Z-24” but we make tiny parts on our machines as well. We are adept with high speed milling and work up to 5 axes. As Apex continues to provide contract manufacturing services, we will continue to push the thresholds of manufacturability. No material or tolerance has impeded our success to date.

Testimonials

-

"We have used the services of Apex Precision successfully on several occasions. The fabricated parts in question are complex machined components requiring a high degree of accuracy"

Mark Pankhurst

Purchasing Manager at Sander Geophysics Ltd.

-

“ . . . Apex has always been one of our top suppliers. Since the inception of Intelligent Hospital Systems, Apex has been beside us step by step creating the perfect machined parts for our medical device, RIVA. Employees of Apex always treat their Customers with the utmost professionalism. . . ”

Sandy Garden

Buyer / Planner

-

I have been working with the APEX Team for over 12 years on a multitude of different projects, from simple to extremely complex. I have had nothing but great experiences with them. They are not simply a high precision machine shop - they thrive at providing support during the conception phase. They have provided CAD and design support and have always delivered projects on-time and within budget. I cannot do other than highly recommend them to anyone I speak to. Thank you APEX!

Michael J Froncioni, BEng., BSc.

Senior Manager, Supplier Quality Engineering