EDM

Various OEM’s

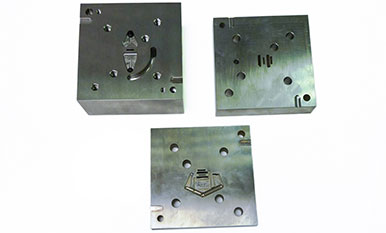

Electrical discharge machining (EDM) is the process of using sparks to erode or remove material. This process allows extreme precision. Apex Precision has made holes with a tolerance of +/-.0001”.

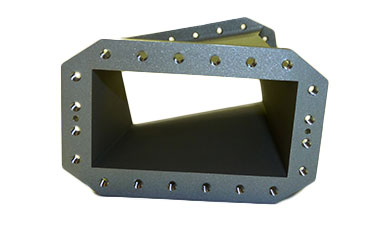

We have used EDM to machine metals with a hardness exceeding 60 Rockwell C. EDM machining also allows the creation of sharp inside corners, often used in the telecommunications and extrusion industries. We can produce sharp inside corners with a radius smaller than .003”.

With over 10 years EDM machining experience, Apex Precision is a leader in manufacturing wave guides, extrusion dies, as well as punch and die sets. Our EDM team has manufactured parts from aluminum, steel, copper, brass, as well as more exotic materials like Inconel, Invar and graphite. If it is conductive, we can EDM machine it.

Testimonials

-

"We have used the services of Apex Precision successfully on several occasions. The fabricated parts in question are complex machined components requiring a high degree of accuracy"

Mark Pankhurst

Purchasing Manager at Sander Geophysics Ltd.

-

“ . . . Apex has always been one of our top suppliers. Since the inception of Intelligent Hospital Systems, Apex has been beside us step by step creating the perfect machined parts for our medical device, RIVA. Employees of Apex always treat their Customers with the utmost professionalism. . . ”

Sandy Garden

Buyer / Planner

-

I have been working with the APEX Team for over 12 years on a multitude of different projects, from simple to extremely complex. I have had nothing but great experiences with them. They are not simply a high precision machine shop - they thrive at providing support during the conception phase. They have provided CAD and design support and have always delivered projects on-time and within budget. I cannot do other than highly recommend them to anyone I speak to. Thank you APEX!

Michael J Froncioni, BEng., BSc.

Senior Manager, Supplier Quality Engineering