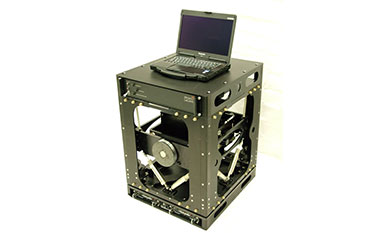

Scintrex

Instrumentation: Apex Delivers Precision

Scintrex required a very fine part that had many different features. The part also had a very precise hole with a tolerance of +/- .001 mm (.00004”). After manufacturing, Scintrex installed a crystal in the precise hole, so the size of the hole was critical to prevent cracking the crystal while not letting it slip out.

Problem

The material selected for this project was Invar 36, which has very good dimensional stability. This helped to measure the precise hole, but Apex had to find a way to repeat the dimension on all the parts. The second challenge on this project was the machining of all the small features at different angles.

Solution

Since the two challenges were actually related, Apex planned the exact manufacturing process before starting any work. The planning helped mitigate potential problems and ensure that the tolerances were respected. A few small adjustments were made during the manufacturing stage to achieve the tolerances.