Medtronic

Medical #1: Engineering Projects

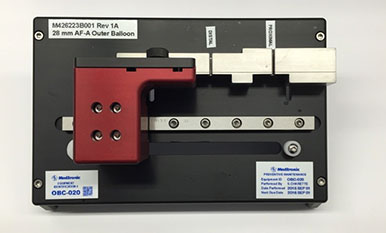

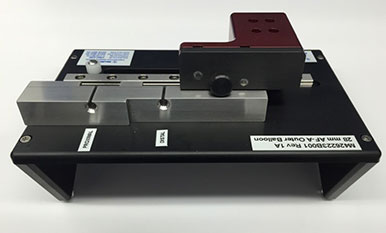

Medtronic manufactures medical devices that require a lot of precision to work properly. One of the devices uses tubes that have to be cut to a specific length, with a tight tolerance on the final dimension. The current cutters often produced tubes that didn’t meet the requirements, so Apex was asked to help develop a prototype for a new cutter.

Problem

The development of product required cooperation between the customer, who brought the medical knowledge, and Apex, who provided the technical expertise. Proper testing, communication and feedback were all crucial to the success of this project. Setbacks were expected, but both parties believed they could be overcome.

Solution

After building an initial prototype, extensive testing was done to see if it produced satisfactory products. Changes required by the customer were incorporated into the next version of the prototype. Apex suggested some design changes to ease manufacturing and operation of the prototype. A second prototype was made and the testing, feedback and redesign loop was repeated a few more times.