Intelligent Hospital

Medical #2: Long-term Relationships

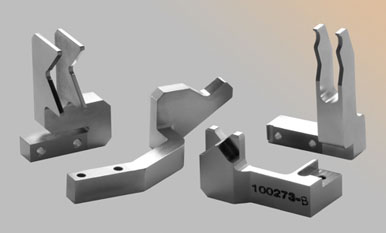

The customer manufactures machines that dispense medication automatically. The machines handle all types of bottles, bags and vials using grippers. Apex provides these grippers, ready to be installed on the machines.

Problem

The grippers are made out of stainless steel 316 because they work in a sanitary environment. The grippers have a lot of thin sections to make them lighter, but machining those sections is a challenge because stainless steel has a lot of stress. The thin sections tend to distort and bend. The other challenge for these parts comes from the plating requirement. All surfaces need to electro polished, which changes dimensions and dulls sharp edges.

Solution

Apex addressed the material stress issue by picking machining methods that reduced the stress in the parts. Since the pars were being repeated, the process was improved over time. The electro polish challenge was solved by communicating the problem to the customer and proposing a solution that involved sharpening of certain edges after plating.